Capsule Filling Machine

Capsule filling machines come in a range of sizes and configurations to meet the diverse requirements of pharmaceutical producers. Available in semi-automatic to fully automatic versions, these units are capable of producing thousands of capsules per hour. They support multiple capsule dimensions and materials, such as gelatin and vegetarian options. Incorporating advanced technology, this specialized pharmaceutical equipment guarantees precise dosing and maintains formulation integrity by preventing contamination during the filling operation.

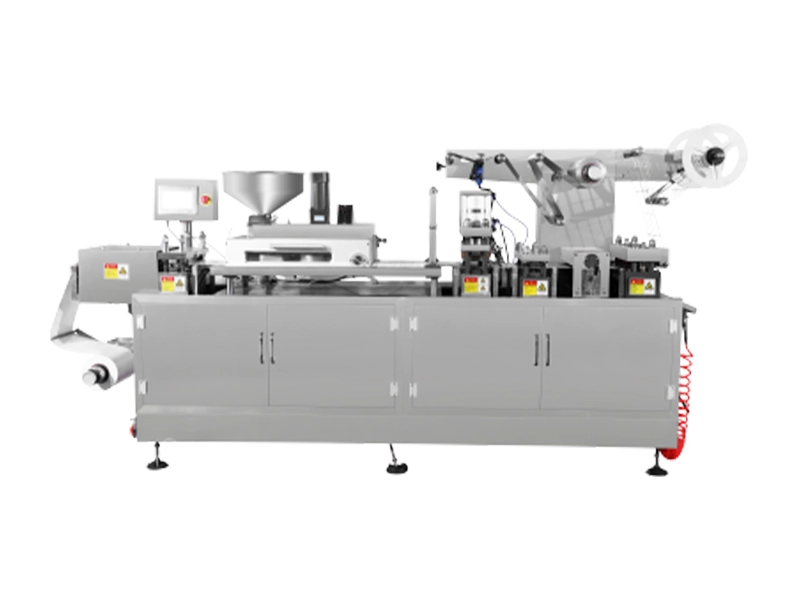

Product Display

Benefits

Fully automatic intermittent motion design, qualification rate exceeding 99%, ensuring smooth and reliable operation.

Multi-bore dosing system maintains filling accuracy within ±3% to ±4%, suitable for traditional Chinese medicine, Western medicine, and health products.

Features an optimized inner turret and Japanese linear bearings, with key components lubricated via a pressure pulverization oil pump for extended service life and noise levels below 75dB.

Equipped with automatic material shortage detection and pause function, along with operator and machine safety mechanisms for secure operation.

Supports capsule sizes from 00# to 4#, and accommodates various filling types such as powder and pellets.

Utilizes touch screen and PLC, along with other high-quality components from renowned international manufacturers, ensuring overall reliability and performance.

Fully automatic intermittent motion design, qualification rate exceeding 99%, ensuring smooth and reliable operation.

Multi-bore dosing system maintains filling accuracy within ±3% to ±4%, suitable for traditional Chinese medicine, Western medicine, and health products.

Features an optimized inner turret and Japanese linear bearings, with key components lubricated via a pressure pulverization oil pump for extended service life and noise levels below 75dB.

Equipped with automatic material shortage detection and pause function, along with operator and machine safety mechanisms for secure operation.

Supports capsule sizes from 00# to 4#, and accommodates various filling types such as powder and pellets.

Utilizes touch screen and PLC, along with other high-quality components from renowned international manufacturers, ensuring overall reliability and performance.

Application

The most common fill type, involving finely milled Active Pharmaceutical Ingredients (APIs) and excipients. This form is suitable for a vast majority of oral solid dosage drugs, such as antibiotics, vitamins, and herbal extracts.

These are small, spherical multiparticulates designed to offer controlled drug release. This multi-unit dosage system can minimize local gastric irritation and provide more predictable bioavailability compared to single-unit forms.

A modern approach where miniature tablets, typically under 3mm in diameter, are encapsulated. This innovative format allows for combining micro-tablets with different release profiles within a single capsule, enabling complex combination therapies.

An ideal solution for poorly water-soluble or oxygen-sensitive drugs. By dissolving or suspending the drug in a lipid-based matrix, this technology can significantly enhance drug stability and bioavailability.

This technique involves enclosing active ingredients within tiny, protective polymer coatings. It is used to achieve targeted or sustained release, effectively mask taste, improve stability, and protect sensitive compounds.

The most flexible filling category, which combines two or more different physical forms—such as powder with pellets, or solids with a liquid—in one capsule shell. This enables the creation of personalized dosage regimens and the development of novel therapeutic solutions.

FAQ

What types of capsules can your capsule filling machines handle?

Our capsule fillers are highly versatile and designed to handle a wide range of capsules. This includes standard hard gelatin capsules (HGC), vegetarian (HPMC) capsules, and specialized capsules like snap-fit and liquid-filled capsules. We provide solutions for sizes from the smallest #5 to the largest .

How does Innoval Pharma ensure dosing accuracy and content uniformity of capsule filling machines, especially for low-dose potent drugs?

Dosing accuracy is at the heart of our design. We achieve this through:

- Advanced Dosing Systems: We offer precise dosing technologies like dosators or tamping pins, which can be selected based on your powder characteristics.

- Superior Powder Handling: Our machines are engineered to maintain consistent powder flow and prevent segregation, which is critical for content uniformity.

- In-Process Control Checks: Optional features like automatic weight check modules provide real-time monitoring and rejection of out-of-spec capsules, ensuring the highest quality standards for even the most challenging potent compounds.

What is the typical output speed range of your capsule filling machines?

Innoval Pharma provides capsule filling machines for every production scale. Our portfolio ranges from laboratory and R&D models (with speeds of a few thousand capsules per hour) for formulation development, to mid-scale production machines, all the way up to high-speed, fully automatic continuous lines capable of producing over 150,000 capsules per hour.

Are your capsule filling machines compliant with pharmaceutical regulations like cGMP and FDA 21 CFR Part 11?

Yes, absolutely. All Innoval Pharma capsule fillers are designed and built to meet global standards, including cGMP and FDA requirements. For regulated environments, we offer FDA 21 CFR Part 11 compliant control systems with full electronic signature and audit trail capabilities. We also provide the necessary documentation to support your validation processes (IQ, OQ, PQ).

How do your capsule filling machines handle complex formulations, such as sticky, cohesive, or low-density powders?

Challenging powders are our specialty. Our engineers have deep expertise in formulation dynamics. We offer customizable solutions to address these issues, which may include:

- Specialized Dosing Systems: Designed for difficult-flow powders.

- Integrated Granulation or Conditioning Units: To improve the flow properties of your powder before filling.

- Anti-Capping and De-dusting Systems: To ensure capsule integrity and cleanliness.

What kind of after-sales support and training can we expect?

Our partnership extends long after the sale. Innoval Pharma is committed to your success through our comprehensive Lifecycle Support:

- On-site Installation & Commissioning

- Hands-on Operational and Maintenance Training for your team.

- Global Spare Parts Network with guaranteed availability.

- Preventive Maintenance Contracts and 24/7 remote technical support to maximize your machine’s uptime.

Unlock Your Medicine Production Potential. Speak with an Innoval Pharma Expert to Tailor Your Solution.

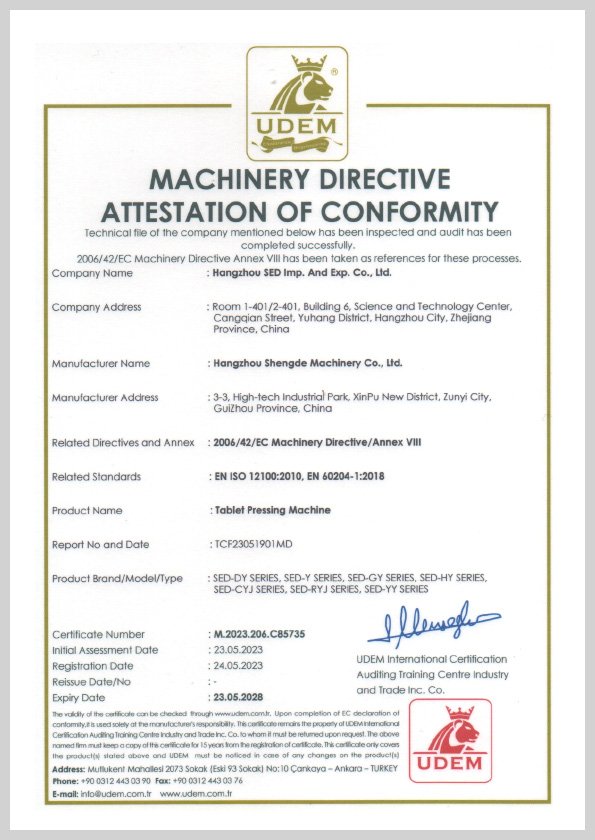

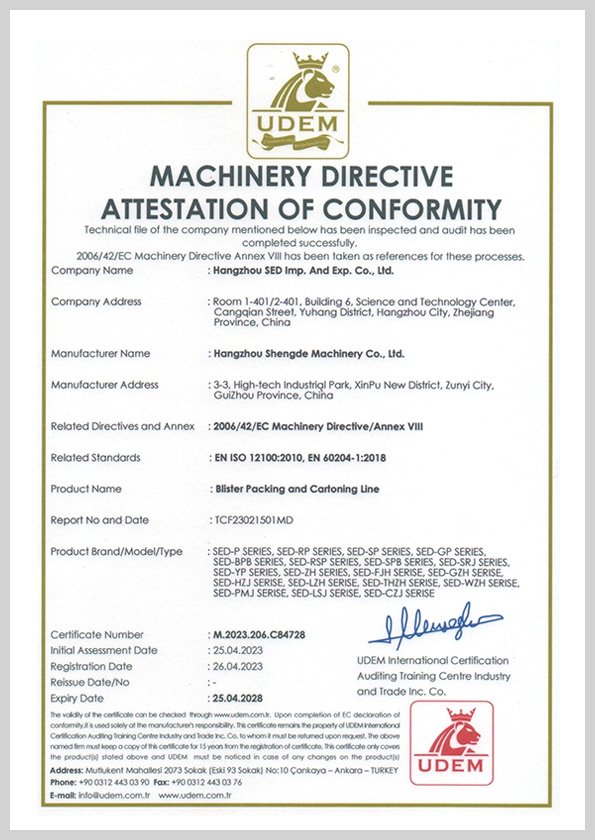

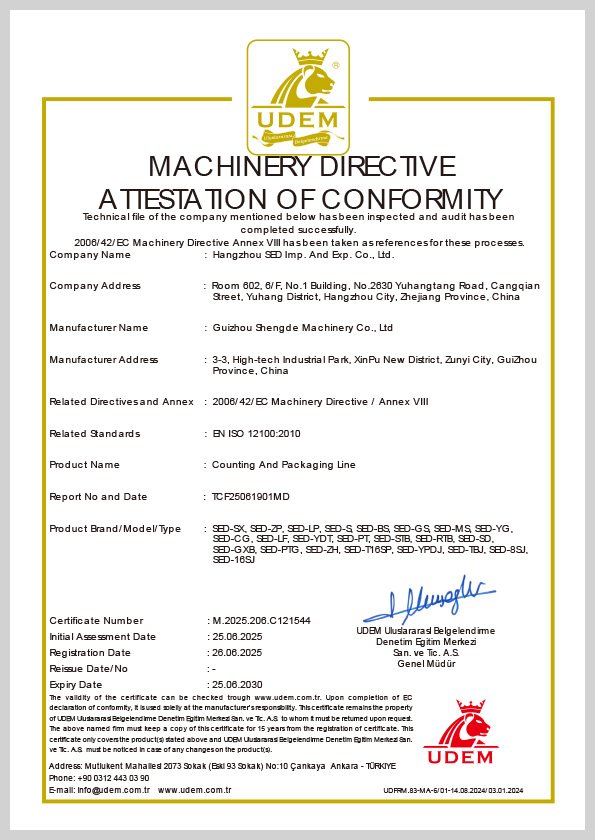

Certificates

Contact Info

Call Us

+1(323)215-9729 (North/South America)

sales@innovalpharma.com

+1(213)258-7721

After Service

+1(909)230-8253 (North/South America)