Table Press

Tablet press is core equipment in pharmaceutical, food and chemical industries, compressing powder/granular materials into tablets efficiently and precisely to meet diverse production needs.

We offer three types for different scenarios: Single-punch tablet press (compact, easy to operate) is ideal for lab R&D and small-batch production – calibrate parameters repeatedly during debugging. Rotary tablet press (multi-station continuous production, uniform tablet quality) is preferred for medium-batch production – clean molds regularly to ensure precision. High-speed tablet press (high capacity, with auto-detection) suits large-scale production – match with material preprocessing equipment to boost efficiency.

Product Display

Benefits

With robust compression force, our presses ensure solid tablet formation and uniform appearance, capable of handling a wide range of material characteristics.

Utilizing standard tooling and a double-sided compression mechanism, the series offers various station configurations and production capacities to meet diverse output needs, from pilot batches to full-scale production.

Integrated with advanced PLC control systems and color touchscreen interfaces for intuitive operation and precise, reliable performance.

Equipped with a closed forced feeder to maintain filling accuracy and tablet weight consistency, even at high operating speeds.

Features real-time pressure monitoring, automatic overload shutdown, and multiple safety protection functions to safeguard both equipment and product integrity.

Built with high-quality electrical components and enhanced cooling systems, ensuring stability and longevity during continuous, high-intensity operation.

The fully enclosed working area with transparent viewing windows and superior sealing effectively contains dust, meeting stringent cleanroom standards.

Contact parts are constructed from stainless steel or specially treated surfaces for easy cleaning and maintenance, preventing cross-contamination and ensuring full compliance with GMP requirements.

With robust compression force, our presses ensure solid tablet formation and uniform appearance, capable of handling a wide range of material characteristics.

Utilizing standard tooling and a double-sided compression mechanism, the series offers various station configurations and production capacities to meet diverse output needs, from pilot batches to full-scale production.

Integrated with advanced PLC control systems and color touchscreen interfaces for intuitive operation and precise, reliable performance.

Equipped with a closed forced feeder to maintain filling accuracy and tablet weight consistency, even at high operating speeds.

Features real-time pressure monitoring, automatic overload shutdown, and multiple safety protection functions to safeguard both equipment and product integrity.

Built with high-quality electrical components and enhanced cooling systems, ensuring stability and longevity during continuous, high-intensity operation.

The fully enclosed working area with transparent viewing windows and superior sealing effectively contains dust, meeting stringent cleanroom standards.

Contact parts are constructed from stainless steel or specially treated surfaces for easy cleaning and maintenance, preventing cross-contamination and ensuring full compliance with GMP requirements.

Application

Single-layer tablets are a fundamental solid dosage form where the medication and excipients are uniformly mixed and compressed into a single, homogenous layer.

Multi-layer tablets are advanced dosage forms that consist of two or more distinct layers of different drug formulations, compressed together to separate incompatible substances or to achieve sequential drug release.

Medicine tablets are solid, pre-measured dosage forms made by compressing powdered active pharmaceutical ingredients with excipients, designed for oral administration to treat or prevent diseases.

Chewable tablets are a type of oral tablet that is intended to be chewed and swallowed without water, often containing pleasant flavors and sweeteners to improve palatability, especially for children or those with swallowing difficulties.

Effervescent tablets are tablets designed to be dissolved in water before ingestion, where they react to produce a carbonated solution, which can enhance the taste and speed up the absorption of the active ingredients.

Laundry tablets are pre-measured, solid units of concentrated laundry detergent that are compact and mess-free, dissolving in the wash to clean fabrics.

FAQ

What types of tablets can your tablet press produce?

Our tablet presses are designed for maximum flexibility and can be configured to produce virtually any tablet type. This includes standard single-layer tablets, complex multi-layer tablets (bilayer, trilayer), chewable tablets, effervescent tablets, and high-density cleaning/laundry tablets. Innoval Pharma will work with you to recommend the perfect model and configuration for your specific formulation.

How complicated and time-consuming is it to change over products or tooling?

At Innoval Pharma, we maximize your operational efficiency. Our presses feature a Quick-Changeover System.

Modular Design: Key components like the turret, feeding system, and tooling can be changed as a unit or module.

Tool-Assisted: The use of dedicated tools significantly reduces downtime.

Typical Duration: For a trained operator, a complete tooling changeover can typically be achieved within 30 minutes, depending on the model and complexity.

What is the production capacity range of your presses? How do we choose the right model for our output?

We offer a complete range of solutions, from R&D and laboratory models (thousands of tablets per hour) to pilot-scale and high-speed, fully automatic production machines (hundreds of thousands to millions of tablets per hour). Our application engineers will consult with you on your current output needs, future expansion plans, product type, and budget to recommend the most cost-effective solution for your business.

Are your machines compliant with international standards like cGMP and FDA?

Yes, absolutely. Innoval Pharma tablet presses are designed and manufactured in strict compliance with international standards, including cGMP and FDA requirements. We provide a complete Validation Support Package to facilitate your DQ, IQ, OQ, and PQ, ensuring a smooth audit process and rapid commissioning for compliant production.

What after-sales service and technical support does Innoval Pharma provide?

We stand behind our machines with a comprehensive “Turn-key” Service:

- Professional Installation & Commissioning by our experienced field engineers.

- Comprehensive Operator & Maintenance Training to ensure your team is self-sufficient.

- Global Spare Parts Supply for fast response and minimal downtime.

- Remote & On-Site Technical Support, including 24/7 remote diagnostics and prompt on-site service.

Unlock Your Medicine Production Potential. Speak with an Innoval Pharma Expert to Tailor Your Solution.

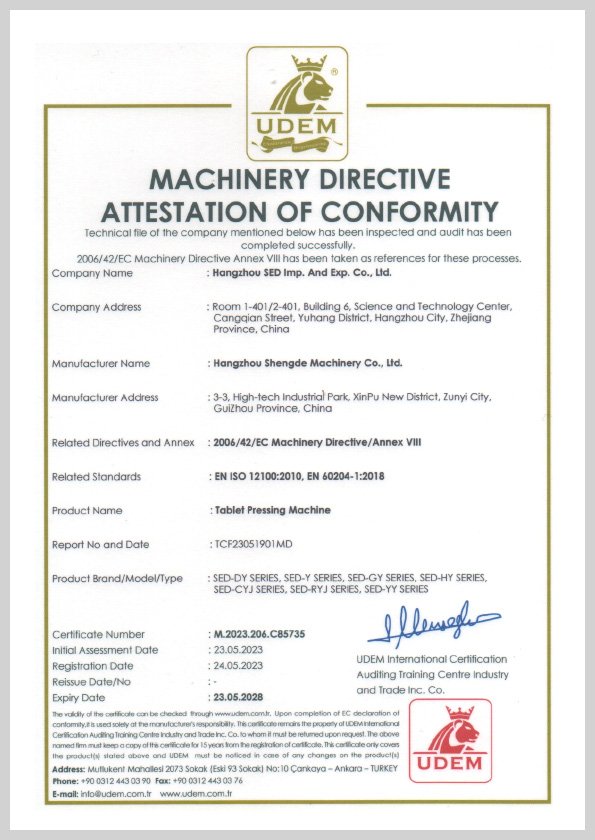

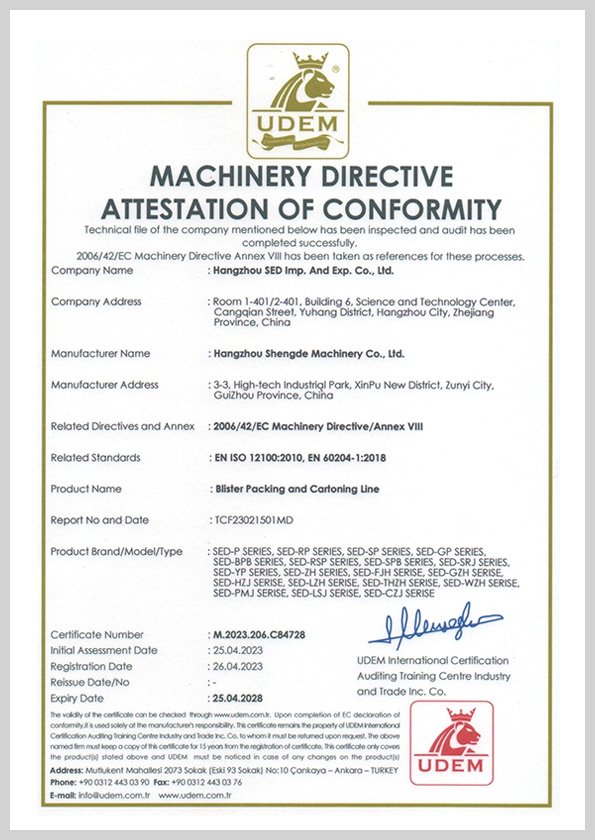

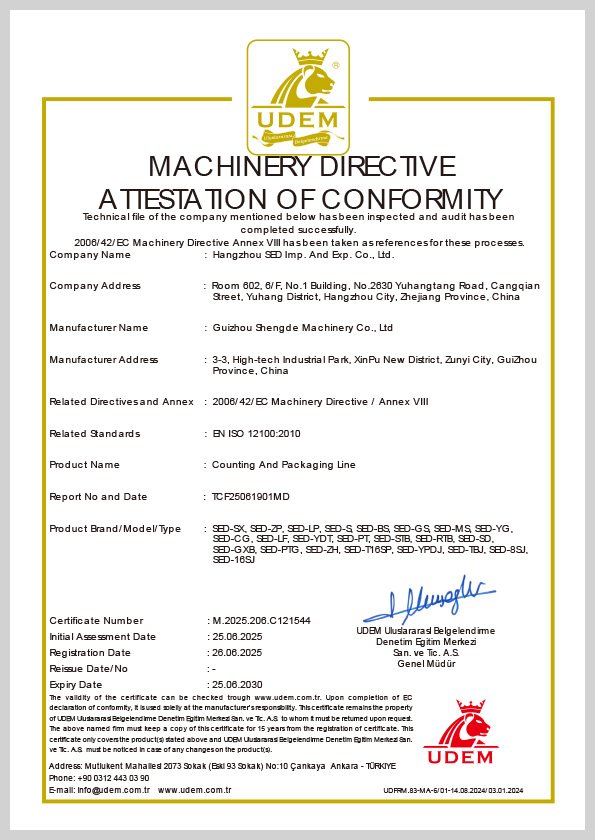

Certificates